Container-type Bagging Machine

- TECHNICAL DATA

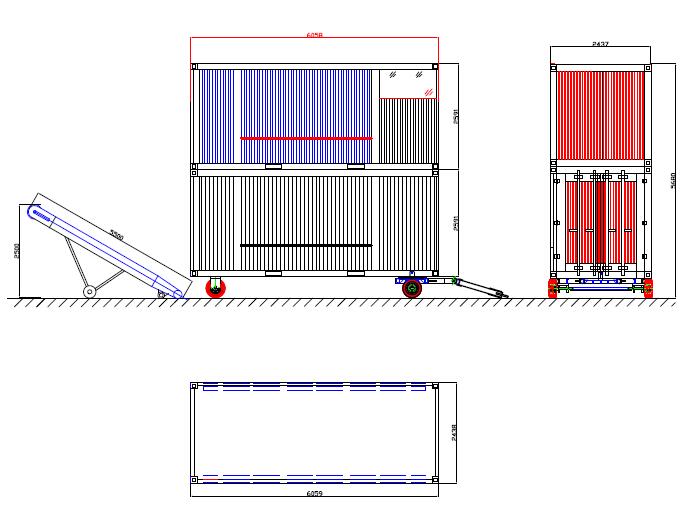

The bagging machine contains bag packing machine, containers, gravity hopper,automatic weighing control system,elecrtric control cabin,conveyor, sewing machine, air-operated system, dust collector and air compressor. These are all put into two containers. The containers are installed with tug, which can be dragged to working place by trailer.

Bagging material: chemical fertilizers, grain, feed, bulk sugar, sulphur, ore and some other free flow materials.

Application: can be used on port, storage yard, warehouse and some other places.

| Model | Production line | Weighing scale | Precision | Bag packing speed | Power source | External dimensions |

| BDM-I | Single line two scales | 25:100kg | 0.2% | 12~20 bags/min | AC380V 12kw | Two containers |

| BDM-II | Two lines two scales | 25:100kg | 0.2% | 24~40 bags/min | AC380V 15kw | Or 6*3*5.8M |

| Working environment | -20℃~+40℃ | Gas pressure | 0.55~0.65MPa | |||

| Packing bag | Open bag, PP woven bag or sacks 800-~1250(L)×500~800(W)mm | |||||

| Way of supplying material | Gravity type, spiral feeding, conveyor belt feeding, vibration feeding combined. | |||||

| Sensor type | Three pivot hanging type | |||||

| Bagging type | Automatic quantitative weighing, artificial bagging, automatic filling, artificial assistance, machine to sewing bag. | |||||