Operation guide of double cylinder(part 2)

Pageviews: Release Time:2017-09-20

Operation guide of double cylinder(part 2)

E.Operation guide

E-1.Electrical Control System Introduction

E-1-1.Composition

The electrical control system controls the grab's opening & closing by controlling the solenoid vavle.

The electrical control system includes: batteries,switch box,remote control,receiver and solenoid valve. Besides,the batteries should be provided with special charger.

E-1-2.Technical Requirements

The electrical control system adopt way of remote control,remote control distance should not less than 50 meters,the signals' emission and receive should be reliable and suitable for various severe environment,working temperature:-10℃~55℃.

Batteries(voltage 24V)

Solenoid Vavle(voltage 24V)

Notes:Check all the electrical joints before operation,if confirmed,turn off the power switch,then turn on the power control switch.

E-1-3.Way of Control

Way of Control: button remote control

Button remote control grab

As show in the pictures,the red part on the back of the remote control is the master switch,↑ is on,and ↓ is off. The red/green indicator lights is for switch and weak power.If the two lights is flickering ceaselesly, please change the batteries.When use the grab:

First,turn on the red switch,the remote control is on,then use the first and second black buttons to operate. The first button is inching button,press it without loosing,the grab is opening ceaselessly,loose it,the grab stop opening.The second button is continuous button,first press,the grab is opening ceaselessly,second press,the grab stop opening.The two last buttons are spare buttons,if the first and the second button donot work any more, you can use the two last buttons after circuit change.

The remote control gives signals to the receiver. The grab opens after the solenoid valve has power.The remote control distance is 100 meters if there is no barriers,and not less than 50 meters indoors.

E-2.spare parts explain

E-2-1.charger

a)---input voltage AC95V~265V 50Hz~60Hz

b)--- max. Power dissipation 0.15~0.18KW

c)---output voltage 24V/12V

d)---out current max.8A according to product require

e)---duration of charge Storage battery depth discharge 80%,need charging 9-11hours

f)---Volume 230×120×86 195×110×65

g)--- Weight 1.5Kg

E-2-2.Valve Regulated storage battery

The battery of the remote control are make up of two set 38AH,12V valve regulated storage battery in series battery box and after series the voltage is 24V.

a.First time use

A battery leaving form our factory with full electric ,the customer can use directly;If place a long time(more than three month),should charge again before use,the way of charge again is make the charger insert into the battery box than link into 220V AC,after the charger turn green light for 3 ~ 4 hours can pull out and use.Charge the battery in a well-ventilated environment.

b.prevent over discharge

Once the battery power used up,should shut off the power,if use pick up voltage to force the grab use.this will cause the battery over discharge and shorten battery life.

c.battery charging.

The storage battery charging not charged in time,charging not enough,over-charging will be a lot of damage for the battery life.So it is prohibited to storage the battery in long time under the without power condition,charging in time after discharge and it need charging more timely with the deeper discharge.not use storage battery more than a week please charging for the battery and not use time more than 2 months must charging with full charge.Another do not use it under the battery in poor condition.

When charging, connect the accumulator with the charger, turn on the electrical source (the input voltage must be consistent with the nameplate range, otherwise the charger couldn’t be turned on), the charger can automatically check extant quantity of electricity and ambient temperature of the accumulator.

Also, it can charge according to the different discharging quantity of electricity of the accumulator. The charger is automatically turned off when the accumulator is fully charged. No matter the reverse polarity or the short circuit and the open circuit of the accumulator, there will be no current output, which can prevent the worker from incorrect operations. Do not need have staff on duty.

Notes:After the grab finished d work,each group storage battery must been charge,when long time not use ,the battery must be placed in dry cool place.The storage battery power will slowly decrease in the use or hold process until no power.This will seriously weakened the life of the battery .To avoid such situation ,we set up a protection measures i circuit,when the battery power is lower than a certain value,power protection device will cut off the circuit,the battery no longer have the power output.If the grab suddenly couldn't action in the process of grab use,it is may be the power are not enough,need to recharge.If the grab produce severe impact or vibration in the process use,this put a high requirements for the electrical line connection,especially for the battery group,it need often remove and installation.The connection of the contacts we choose the waterproof flexible seal joint,both safe and reliable and convenient save trouble.

E-2-3.Remote control

Grab electric control system using wireless remote control ways,control distance is not less than 50 meters,signal transmission and reception should be reliable ,is suitable for field port area,etc all kinds of environments,environmental work from -10 ℃ temperature to 55 ℃.

The remote control is make up emitter and sign receiver .

E-3.Operation guidance

E-3-1.Grab preparation

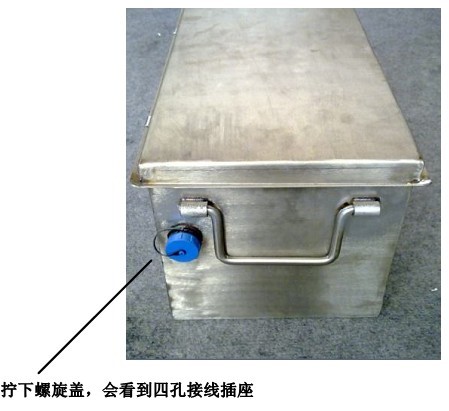

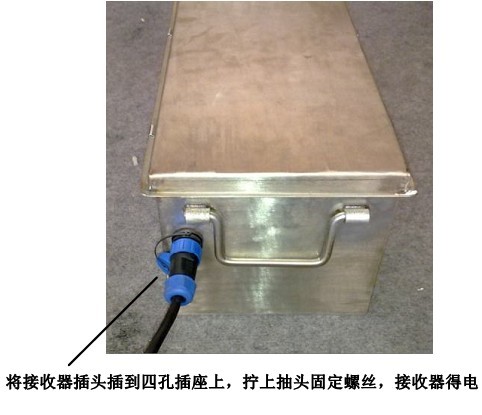

a)---Replace the charged up electric battery,let the plug on the receiver link to the battery case as the picture shown:

Twist the spiral cover, will see four holes wiring socket

Make the receiver plug inserted into the four hole electrical outlet,twist the tap and fixed the screw,the receiver get electricity.

b)--- Before work ,check all of the electric joint,after confirmed,closed the power switch,turn on the power control switch.

E-3-2.grab regular work

a)---grab open

When need to open the grab,press the remote control emitter button,this time the signal receiver receive the signal,battery valve get electric ,oil cylinder been unlocked ,grab open with the oil cylinder piston rod reach out.

Press the "open" button,solenoid valve get electricity,oil cylinder unlocked and grab open, loose the button and solenoid valve no electricity,the oil cylinder was locked,the grab stop to open.

Press the "keep open"button,solenoid valve continues electricity,grab continues open until up to the maximum.If this time need to close the grab ,click to the "keep open"button again,solenoid valve no electricity,oil cylinder was locked.

b)---grab close

Put the open grab to the bulk cargo,hosting the grab and make sure the solenoid valve power turn off ,hosting the grab,grab closed.

E-3-3.Emergency treatment

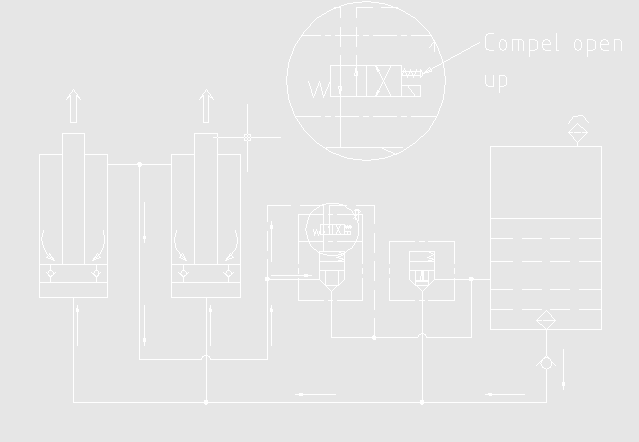

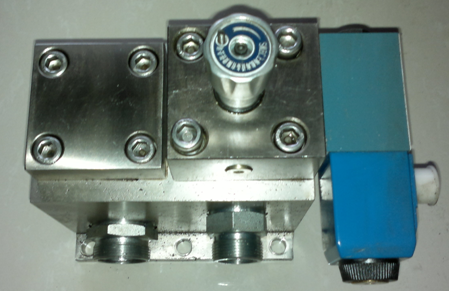

When the grab's electrical system or the remote control system have malfunction,or based on repair,we can use a 6mm hard shaped object to top the solenoid valve forced open the switch.

When operation,if discovery the remote transmitters failure or lost carelessly which may caused the grab not open,this time we can adopt manually way let the grab open.

Option 1---Grab landed,start the manual directional control valves,forced the solenoid valve and main valve core separate,unlocked the oil cylinder,hosting the grab,oil cylinder piston rod reach out,grab open.

Option 2---The manual directional control can be set to become a leash control,forced the electromagnetic valve part from the main valve core,grab open in the air.

E-3-4.grab stop operation

Before the grab stop operation, middle beam down,making the oil cylinder piston rod completely withdraw,in order to avoid the piston rod exposed and corrosion.

When the grab stop operation should cut off the power,if take out the storage battery,the plug of storage battery need covered by rubber sleeve in order to avoid water erosion.and use the waterproof cloth cover the entire grab(the user bring along by their own),prevent the water corrosion the grab's electric appliances and hydraulic components.

When the grab stop operation,should flush clean ,clear the down beam plate、middle beam inside and the material which inside on all rotating components and the material which is inside on the grab scoop,avoid the scoop、middle beam accumulate material,water and caused corrosion.

All of the rotation axis pin of the grab should been add grease enough.

If grab don't work long time,should be a movement every 2 months, in case the corrosion and hydraulic oil inside the control component generation colloid.